Unlocking the potential of bespoke hardware solutions is a key driver for innovation across various industries, from high-performance computing to specialized medical equipment.

Custom hardware service provides the critical link between design and functionality, translating abstract concepts into tangible, problem-solving realities.

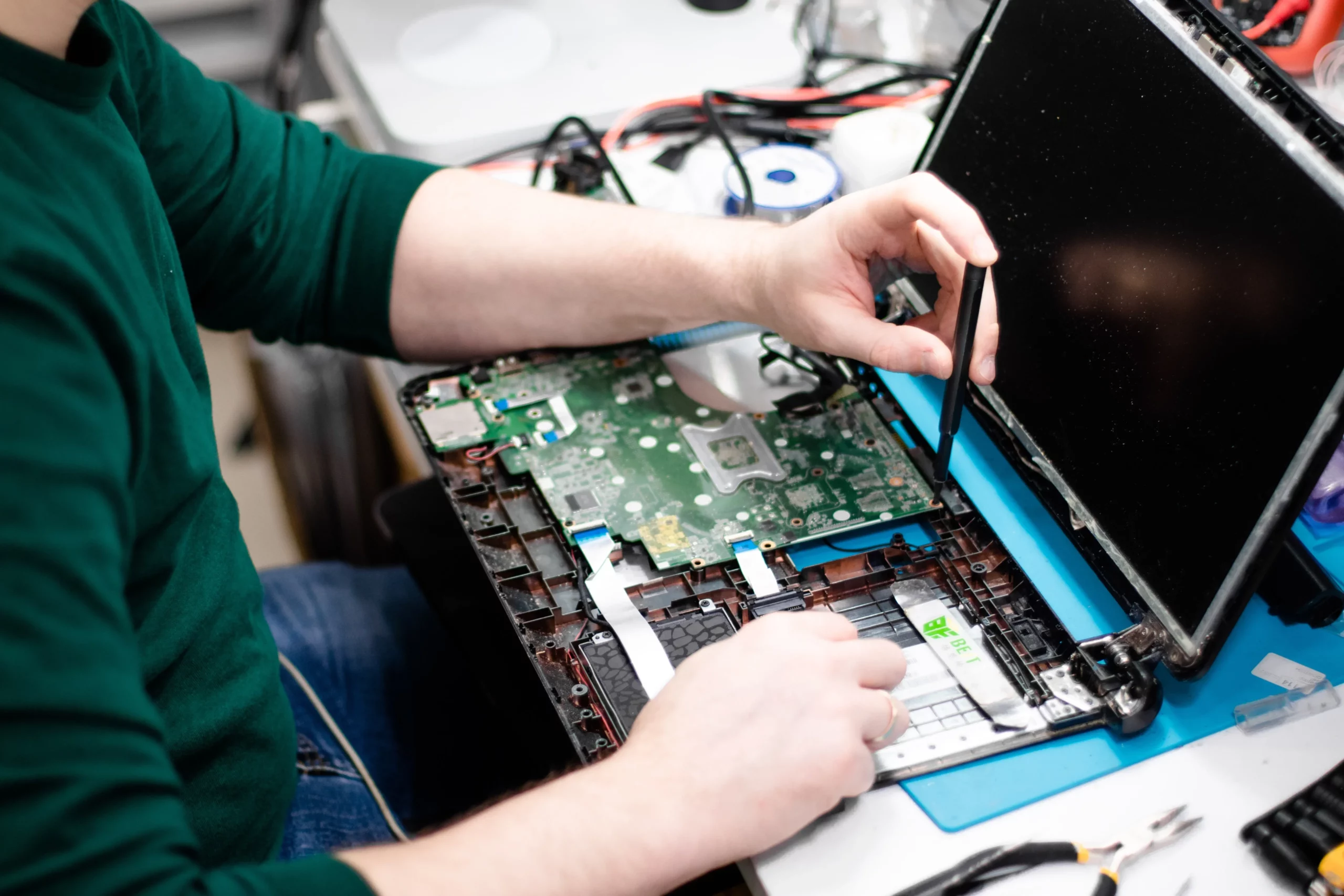

From intricate circuit board designs to the meticulous assembly of complex components, this specialized field allows businesses to craft systems tailored to their precise needs.

This approach, often overlooked, offers significant advantages over readily available off-the-shelf products.

The highly customized nature of custom hardware service empowers engineers and technicians to overcome limitations imposed by conventional technology.

Imagine needing a power supply that surpasses industry benchmarks, or a specialized sensor array for real-time data acquisition. A dedicated custom hardware service provider can expertly engineer and fabricate these solutions.

This personalized approach is crucial for businesses seeking edge-case solutions, demanding efficiency, and high-performance results. A perfectly configured system, engineered to the precise specifications of the user, can lead to unprecedented operational advantages.

This article explores the multifaceted world of custom hardware service, dissecting its core principles, demonstrating the intricate processes involved, and showcasing real-world applications that demonstrate the tangible benefits of meticulously crafted hardware solutions.

The Core Components of a Custom Hardware Service

A robust custom hardware service hinges on a deep understanding of client requirements and a commitment to meticulous execution at every stage of the design and manufacturing process.

This specialized field is critical for tailoring hardware solutions to meet exacting specifications, exceeding the limitations of pre-built or off-the-shelf options.

Effective custom hardware service involves a seamless collaboration between engineers, designers, and technicians, each contributing their expertise to refine the design and deliver a fully functional product.

Client communication plays a vital role in the success of a custom hardware service, ensuring the final product directly addresses the client’s unique challenges and opportunities.

The core of this service often lies in the detailed prototyping and testing phases, where potential issues are identified and corrected before production begins. This proactive approach minimizes costly mistakes and ensures the end result precisely meets the desired specifications.

From initial concept sketches to final product delivery, a comprehensive project management approach is essential for a successful custom hardware service. This encompasses careful scheduling, resource allocation, and consistent progress tracking.

High-quality custom hardware service relies on advanced manufacturing techniques, including precise machining, component assembly, and advanced circuit board fabrication. This expertise allows for the production of complex and sophisticated custom hardware systems.

A significant aspect of any successful custom hardware service is ongoing support and maintenance. This post-production stage is crucial for ensuring the hardware continues to operate optimally and addresses any emerging issues or enhancements.

The ability to handle intricate modifications and upgrades throughout the product’s lifecycle is a key differentiator for a superior custom hardware service. This adaptability is essential for maintaining the value and effectiveness of the bespoke solution.

A dedicated custom hardware service will leverage advanced diagnostic tools and technical expertise to address issues that may arise and refine existing products over time. This proactive approach guarantees longevity and effectiveness of the custom-built hardware.

The emphasis on quality control and rigorous testing throughout the entire custom hardware service process ultimately ensures the delivery of a reliable and high-performing product tailored to the client’s precise needs.

The Core Components of a Custom Hardware Service

A robust custom hardware service hinges on a deep understanding of client requirements, encompassing the precise specifications and intended applications of the desired hardware.

This detailed knowledge forms the bedrock upon which a tailored solution is built, ensuring the final product directly addresses the client’s specific needs.

Meticulous documentation and communication are critical, ensuring all stakeholders are aligned on the project’s objectives and technical specifications from inception to completion.

The service’s success depends significantly on the precise analysis of current limitations, allowing engineers to identify potential bottlenecks and incorporate enhancements.

Expert engineers, skilled in a range of technologies, are essential for a custom hardware service, ensuring technical viability and feasibility.

From initial concept validation to final product testing, a seasoned team of engineers can provide invaluable insights, mitigating risks and facilitating design refinements throughout the development process.

The design phase of a custom hardware project requires a strong focus on the integration of components, carefully considering electrical compatibility, thermal management, and overall performance.

Thorough prototyping and testing procedures are necessary for iterative refinements, verifying functionality and identifying potential flaws.

Prototyping is an integral part of the custom hardware service process, allowing for adjustments and optimizations prior to final production.

The iterative nature of this process ensures the final product not only meets but also exceeds initial expectations.

Manufacturing processes for bespoke hardware often require specialized equipment and expertise. A high level of quality control is paramount at every step, ensuring the product meets stringent standards.

This meticulous attention to detail across the entire production lifecycle is crucial in achieving the highest standards of quality and reliability for custom hardware.

A comprehensive understanding of potential challenges throughout the development lifecycle is essential, encompassing factors such as material limitations, manufacturing constraints, and regulatory compliance.

Comprehensive documentation and meticulous record-keeping allow for a clear audit trail, facilitating any future modifications or troubleshooting efforts.

A well-structured project management system is essential for efficient execution, ensuring timely delivery while maintaining budgetary constraints.

The ability of a custom hardware service to adapt to evolving client needs and market demands is also crucial to its success, fostering long-term partnerships based on trust and mutual understanding.

Ultimately, the success of a custom hardware service hinges on the proactive identification and mitigation of potential issues, ensuring a seamless and efficient workflow from design to delivery.

Custom Hardware Design and Prototyping

Custom hardware design and prototyping is a critical component of custom hardware service, enabling clients to realize their specific technical visions.

This stage involves the meticulous planning, creation, and testing of unique electronic components, circuits, and systems tailored to the client’s unique needs and specifications. It bridges the gap between abstract concepts and tangible, functional hardware.

The importance of custom hardware design and prototyping lies in its ability to produce bespoke solutions that address particular problems or opportunities. Often, off-the-shelf components simply don’t meet the specific requirements of complex projects, necessitating the creation of novel designs.

This process frequently involves initial consultations and detailed discussions with the client to understand their precise needs and desired outcomes. Thorough documentation, including schematics, layouts, and functional specifications, is essential throughout the custom hardware service lifecycle.

In the prototyping phase, custom hardware designs are constructed and rigorously tested to ensure they meet performance, reliability, and safety standards. This iterative process allows for refinements and adjustments before full production, thereby minimizing the risk of costly errors later on.

Effective custom hardware design and prototyping relies heavily on skilled engineers with expertise in electronics, embedded systems, and microcontrollers. This expertise is invaluable in developing solutions that are robust, efficient, and reliable for various applications.

Furthermore, design software, simulation tools, and appropriate fabrication facilities are essential for successful prototyping and final product delivery. These tools aid in ensuring the integrity of the design, reduce development time, and ultimately, help to deliver on the client’s specific needs.

The results of successful custom hardware design and prototyping are the realization of innovative solutions tailored to address the very unique specifications of each client’s project, ranging from intricate electronics for industrial applications to the precise integration of custom chips within new products. This detailed, iterative approach is fundamental to providing high-quality custom hardware service.

As a critical stage of the custom hardware service, the careful design and robust prototyping process dramatically increases the chances of a successful final product that meets the client’s exact requirements, minimizing potential issues and ensuring a better user experience.

By focusing on custom hardware design and prototyping, the service provider can achieve a superior outcome in the long run, ensuring product quality, meeting deadlines, and exceeding client expectations throughout the entire project.

Custom Hardware Integration and Testing

The fourth key element of our custom hardware service is the meticulous integration and rigorous testing phase.

This stage ensures that all custom-designed hardware components function seamlessly together and meet the specific performance requirements outlined by the client.

Thorough testing procedures, from individual component verification to complete system validation, are integral to delivering a reliable and high-performing custom hardware solution.

This crucial step involves verifying the compatibility of each component within the intricate custom hardware design, meticulously evaluating power consumption, identifying any potential thermal issues, and ensuring adherence to the desired performance benchmarks.

Rigorous testing is not just about achieving the expected specifications; it’s also about proactively identifying and resolving potential weaknesses and limitations before the hardware is deployed, minimizing the risk of unexpected failures and enhancing the longevity of the custom hardware service.

Detailed test reports and documentation, including performance metrics, thermal profiles, and stability data, are generated for each custom hardware solution, providing valuable insights into the effectiveness and reliability of the components and the overall design.

This comprehensive approach to integration and testing is fundamental to delivering quality assurance and exceeding client expectations for their custom hardware needs.

By emphasizing rigorous testing, we ensure that our custom hardware service not only meets but surpasses the specified design parameters, guaranteeing a high degree of reliability and stability in the deployed custom hardware solution.

In today’s rapidly evolving technological landscape, the need for tailored solutions is paramount, and custom hardware service plays a critical role in meeting this demand.

From specialized embedded systems to high-performance computing clusters, the ability to design and fabricate unique hardware components is crucial for achieving optimal results in various industries.

This article has highlighted the benefits of custom hardware service, demonstrating how tailored solutions can lead to improved efficiency, reduced costs, and enhanced performance.

The intricate details of specific requirements, from power consumption to thermal management, can be meticulously addressed through custom hardware service, unlocking opportunities that off-the-shelf components simply cannot provide.

Ultimately, leveraging the expertise of a reputable custom hardware service provider ensures that businesses and researchers alike can realize the full potential of their projects, whether it’s developing cutting-edge medical devices, creating advanced industrial control systems, or pushing the boundaries of scientific discovery. Companies that prioritize custom hardware service are not just building products; they are building a competitive edge, leveraging the unique advantages offered by tailored design and manufacturing.

The ability to adapt and innovate is essential in any sector, and custom hardware service empowers businesses to achieve these goals, fostering a future powered by bespoke, high-performance solutions.